The following article by CARES PhD student Angiras Menon is taken from the 11th CARES Research Report.

The generation of energy relies heavily on the combustion of fossil fuels, with nearly 85% of the world’s primary energy sources coming from consumption of these fuels. Even with the increasing role of renewables in energy generation, curtailing emissions from combustion processes must be prioritised if countries such as Singapore are going to meet the stipulations of international agreements on climate change such as the 2016 Paris Agreement. The main emissions from combustion that contribute to radiative forcing and global climate change are gaseous products, for example CO₂, NOx and methane. However, the second largest major contributor to global climate change is soot, the solid particulate matter that forms during combustion. Newer emission regulations, such as Euro 6, are recognising the importance of soot and are now also placing restrictions on the size and number of soot particles that can be emitted from engines. In order to meet these agreements and regulations, we require a deeper understanding of how soot forms.

Here at CARES, we make use of a variety of computational and experimental techniques to develop multiscale mathematical models of soot formation in flames. These models will help guide the design of cleaner fuels and more efficient engines.

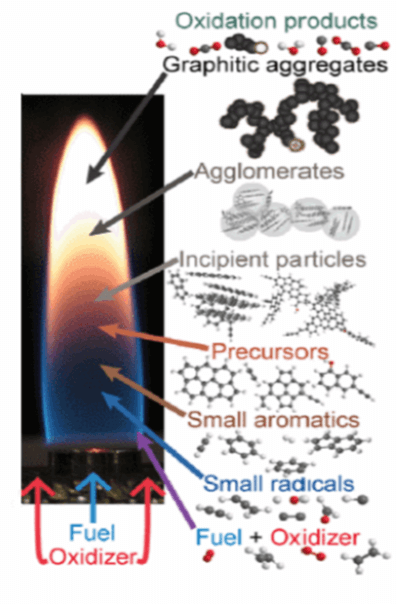

Soot formation involves several complex chemical and physical processes. First, the fuel breaks down into smaller molecules in pyrolysis, before a sequence of chemical reactions generates polyaromatic hydrocarbons (PAHs). These PAHs then come together to form the first soot particles, which then undergo various particle processes before being emitted. Our research group at CARES and Cambridge has developed a comprehensive particle model that describes how soot grows once it forms, but the mechanism of inception where the PAHs actually form soot has been an open question for decades. This is a key problem, as most models are highly sensitive to how the soot formation is described.

The different particles produced in a candle flame.

Credit: Hope A. Michelsen

Combustion Energy Frontier Research Centre, 2016

As such, recent work at CARES has focused on discovering how inception of soot occurs by trying to identify what types of PAHs are most important in the process. At CARES, we have shown that curved PAHs are able to interact with each other as well as with charged molecules in the flame, thereby stabilising them. Recent work in the community has also highlighted the role of radical PAHs, which are able to grow quickly by rapid chain reactions. Our work at CARES applies computational chemistry methods to test these various hypotheses of how soot forms. By computing the optical properties of PAHs, we have shown that only a narrow range of PAH sizes are likely to form soot. We are also developing kinetic and thermodynamic models to describe how fast and how likely these different PAHs form, and comparing them to our flame experiments from the laboratory. By researching soot formation, we hope to be able to identify a range of operating conditions (temperature, pressure, type of fuel) where soot formation is unfavoured, so that particulate emissions from combustion can be reduced in the future.

Angiras Menon received his B.A. and M.Eng. degrees in chemical engineering from the University of Cambridge in June 2016. He joined the Computational Modelling group in Cambridge in October 2016 as a PhD student under Prof. Markus Kraft. Angiras’s research project involves using computational chemistry tools, particularly density functional theory, to study the gas-phase chemistry leading to the formation of carbonaceous nanoparticles formed in flames and engines. He is also interested in reaction kinetics, molecular dynamics and optimisation techniques as applied to problems in combustion and renewable energy.